Contact us

6, Three Spires House

Station Road, Lichfield WS13 6HX

Testing Services

Our carbon steel plates are certified to EN 10204:2004. The actual type of certificate that is issued will be dependent of the particular plate supplied, details of this certification are listed below. Please note, we only provide testing services on material supplied by us.

EN10204:2004 3.1

This certificate is issued by the mill as a declaration of compliance with the specification and includes test results which are validated by the mill’s own in–house testing department. It is a requirement that this testing arrangement is completely separate and independent of the manufacturing centre.

EN10204:2004 3.2

A more demanding inspection where the steel is inspected not only by the mill but by a third party such as Lloyds Register or TUV. The third party will countersign the certificate which states that the plates are fully compliant with the specification and the test certificate is issued.

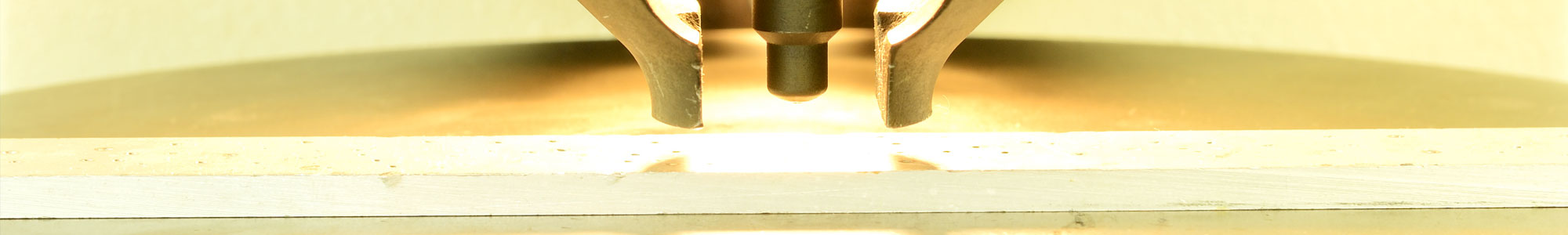

Charpy V Notch Impact Testing

The test involves the use of a steel specimen measuring 55 x 10 x 10mm which is supported at both ends and subjected to a pendulum blow behind a machined notch which is either ‘U’ or ‘V’ in shape.

The energy absorbed in fracturing the specimen (measured in Joules) is calculated by the height to which the pendulum rises after breaking the test piece. The test itself can be carried out in a variety of temperatures to determine material performance at either increased or cryogenic temperatures.

For carbon steels at higher temperatures the test specimen will fracture by a ductile mechanism whilst at low temperature the fracture is of a brittle nature absorbing much less energy. Within the transition range between the two extremes both ductile and brittle fracture is observed.

The test results can be based around absorbed energy, lateral expansion, fracture appearance or a combination. The actual Charpy impact test can vary due to being subjected to specific standards.

Test Specimen and Testing Rig – Characteristics

Designation: mm

Length of test piece: mm

Width of test piece: mm

Angle of notch: Degree

Distance between anvils: mm

Angle of taper of each anvil: Degree

Radius of curvature of striker: mm

Energy absorbed by breakage KU or KV: Joule

Height of test piece: mm

Height below notch: mm

Radius of curvature of base of notch: mm

Radius of anvils: mm

Angle of taper of striker: Degree

Width of striker: mm

About Ductile to Brittle Transition

Notched bar impact testing of a specimen over a temperature range will show a change from ductile fracture at higher temperatures to brittle fracture at lower temperatures revealed by a drop in impact energy. This testing raises the important issues concerning the fracture toughness of steel which can change dramatically over a relatively small temperature range.

Consideration should therefore be taken when using steel in particular working environments, especially ones where significant temperature variation is commonplace.

Ultrasonic Steel Testing

Ultrasonic testing is a non-destructive testing (NDT) method where ultrasonic waves are passed over the material or specimen to check for internal flaws.

An ultrasound transducer which is hooked up to a diagnostics machine is separated from the material by a couplant that improves the transmission of ultrasonic energy for testing purposes. For steel testing, water or oil can be used as a separating method.

The test is highly penetrative, detecting potential flaws deep into the material and has great accuracy especially when compared with other non-destructive testing methods. Furthermore, this testing method is also very portable which means that steel material can be tested on site if required.

The reflected ultrasound wave is measured for consistency – if the amplitude wave is not consistent, this will be indicative of a flaw in a material. A good example of an ultrasound test would be for measuring the thickness of pipe. Ultrasonic inspection is not suitable for surfaces which are very small, with a rough surface or irregular in shape – however the testing method lends itself well to heavy steel plates, pipes and fabricated sections due to the consistent nature of the product.

Masteel are able to arrange for your steel order to be inspected by a third party testing house, and ultrasonic inspection is one of many testing services we offer.

Magnetic Particle Inspection

Magnetic Particle Inspection (MPI) is a non-destructive testing method where an electrical current is passed through a test specimen forming a magnetic field.

The test is intended to establish if the continuity of the material is intact and identifies surface and near surface flaws. Once magnetised, if there is any discontinuity in the material, the magnetic field will leak. Iron particles are applied to the specimen and if an area of leakage is present the iron particles will be attracted to this area. The build up of these particles indicates potential flaws in the material which can then be investigated further.

Magnetic Particle Inspection is an excellent method for detecting surface or near surface cracks in the material. The specimen should be tested in two directions at 90 degrees because it is possible that a surface crack could be following the direction of the magnetic field. If this were the case the field is unlikely to be interrupted and therefore no flaw would be identified.

HIC Steel

The test is also very useful when supplying steels which need to show resistance to the effects of Hydrogen Induced Cracking (HIC). Pressure vessel and boiler grade steels will benefit greatly from such a test especially if the steel is to be used in sour gas service.

The test cannot be used on austenitic steels nor will it identify deep flaws in the material inspected.

Masteel offers third party magnetic particle inspection as one many testing services available to our clients. For more information about our testing services please click here to contact Masteel today.

High Temperature Tensile Testing

High temperature tensile testing is a procedure to test the properties of a material at above room temperature. The test, as covered by the ASTM E 21 standard, will determine the following parameters:

- Tensile strength (breaking strength)

- Yield strength

- Elongation

- Reduction of area

Specialist testing, measurement and control equipment is required to perform this test.

The results of such a test will provide a good indication of the static load bearing capacity of the material and therefore establishes the suitability of a material for its intended purpose.

Simulated Post Weld Heat Treatment

Conventional welding processes, which rely upon the local melting and fusion of material, generate significant residual stress distributions in the weldment. The extent of these stresses can, under conditions of high restraint, approach the yield strength of either the parent or weld materials itself.

Post-weld heat treatment (PWHT) is applied to welded steel assemblies, with its primarily objective to reduce the possibility of brittle fracture. The benefits of post-weld heat treatment include a significant reduction of tensile residual stresses in the weld joint and, to a lesser extent, tempering of the heat-affected zone and the weld metal microstructures.

Post-weld heat treatment of C-Mn steels is typically carried out at approximately 600°C, for one hour per 25mm of thickness.

Masteel UK Limited in collaboration with a UKAS accredited laboratory can arrange simulated post-weld heat treatment of its products with fully documented heat treatment charts traceable to national standards.

Our clients can therefore be confident that the material supplied which may be subject to post weld heat treatment in production has already been certified in the required condition.